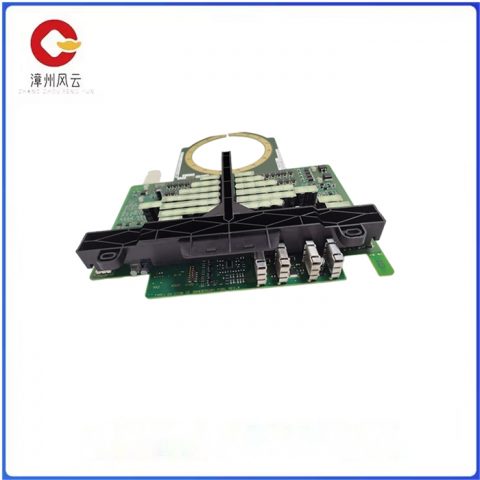

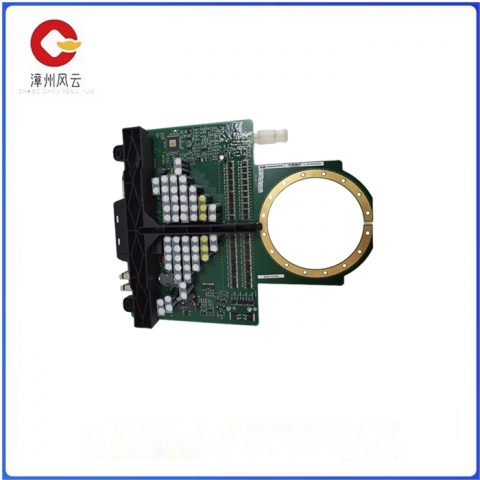

NAMU-01C Auxiliary measurement performance module improves measurement accuracy

ABB’s NAMU-01C-64702475D Auxiliary Measurement Performance module is designed to improve measurement accuracy and performance of hydraulic systems in a variety of industrial automation applications. It complements the main control module of ABB’s servo valve controller, providing additional processing power, advanced algorithms, and dedicated functions to optimize hydraulic system performance.

Main features:

Advanced signal processing: The NAMU-01C module uses advanced signal processing technology to filter out noise, compensate for nonlinearity, and improve the accuracy of sensor data.

Adaptive gain control: It has an adaptive gain control algorithm that automatically adjusts the gain of the measurement channel according to operating conditions, ensuring optimal signal amplification and minimizing measurement errors.

Temperature compensation: This module includes a temperature compensation function that corrects for the effect of temperature changes on sensor readings to maintain measurement accuracy over a wide temperature range.

Predictive maintenance: The NAMU-01C module can be used for predictive maintenance purposes by analyzing sensor data to identify potential problems before they lead to failure.

Data logging and Analysis: Support for data logging and analysis enables users to collect, store, and analyze measurement data for performance monitoring and optimization.

Benefits of using the NAMU-01C auxiliary Measurement performance module:

Enhanced measurement accuracy: The module’s advanced signal processing and adaptive gain control capabilities significantly improve the accuracy of sensor measurements, providing more reliable and accurate data to the control system.

Reduced measurement errors: By compensating for nonlinearities and temperature variations, the NAMU-01C module minimizes measurement errors, resulting in more stable and predictable system behavior.

Improved system performance: Improved measurement accuracy and reduced measurement errors help improve overall system performance, including smoother control, reduced oscillations, and increased efficiency.

Predictive maintenance and reduced downtime: The predictive maintenance features enabled by the module help prevent unplanned failures and reduce downtime and maintenance costs.

Data-driven decision making: Data logging and analysis capabilities facilitate data-driven decision making, enabling users to optimize system parameters, troubleshoot problems, and identify areas for improvement.

NAMU-01C

Precautions for implementing NAMU-01C module:

Compatibility with servo valve controllers: Ensure compatibility between the NAMU-01C module and specific ABB servo valve controller models to ensure seamless integration and correct communication.

Sensor calibration and configuration: Properly calibrate and configure connected sensors to ensure accurate and reliable measurements.

Parameter optimization: Optimize module parameters, such as gain Settings and filter coefficients, according to specific application and system requirements.

Data recording and analysis tools: Collect, store and interpret measurement data efficiently with appropriate data recording and analysis tools.

Maintenance and updates: Perform regular maintenance and apply software updates to keep modules and associated software up to date and functioning optimally.

By carefully considering these factors and thoughtfully implementing the NAMU-01C Assisted Measurement Performance module, industrial automation systems can achieve higher measurement accuracy, reduced measurement errors, improved system performance, predictive maintenance capabilities, and data-driven decision making, increased productivity, reduced downtime, and improved operational efficiency.

There are no reviews yet.