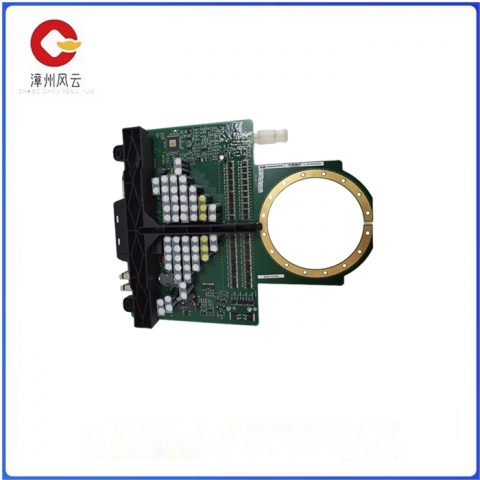

503-26606-21|Servo driver|MSC II Motion controller

503-26606-21 Servo drive technology, as one of the key technologies of CNC machine tools, industrial robots and other industrial machinery control, has been widely concerned at home and abroad. In the last 10 years of the 20th century, the development of microprocessor (especially digital signal processor – DSP) technology, power electronics technology, network technology, and control technology has laid a good foundation for the further development of servo drive technology. If the 1980s was AC servo drive technology to replace DC servo drive technology, then the 1990s is the servo drive system to achieve full digital, intelligent, networked 10 years. This is particularly evident in some industrially developed countries.

503-26606-21 servo drive is divided into position ring, speed ring and current ring according to its control object from outside to inside, and the corresponding servo drive can work in position control mode, speed control mode and torque control mode. When the servo drive works in any mode, its corresponding mode can be set by three ways: 1. 2. Internal setting of parameters; 3, communication given. The internal given application of the parameter setting is relatively small, and it is limited graded adjustment.

503-26606-21 The advantage of using analog quantity given is that the response is fast, applied to many high-precision and high-response occasions, the disadvantage is that there is zero drift, which brings difficulties to debugging, European and American servo systems use this way. Pulse control is compatible with common signal modes: CW/CCW (positive and negative pulse), pulse/direction, and A/B trust signal. The disadvantage is that the response is slow, and Japanese and domestic servos use this way.

503-26606-21 I of course the most respected communication given way, which is also the European brand commonly used control method, the advantage is given quickly, fast response, can reasonably carry out motion planning, especially suitable for CAM control and flying positioning method, 2012 high-grade CNC machine tools use this way. Communication is usually given as bus communication, point-to-point communication and network communication.

There are no reviews yet.